Is the Harder a Material, the More Wear Resistant?

- Share

- Issue Time

- Jun 26,2019

Summary

For pure material, this is indeed the case: the harder the material, the more resistant it is.

Is the harder a material, the more wear resistant?

For pure material, this is indeed the case: the harder the material, the more resistant it is.

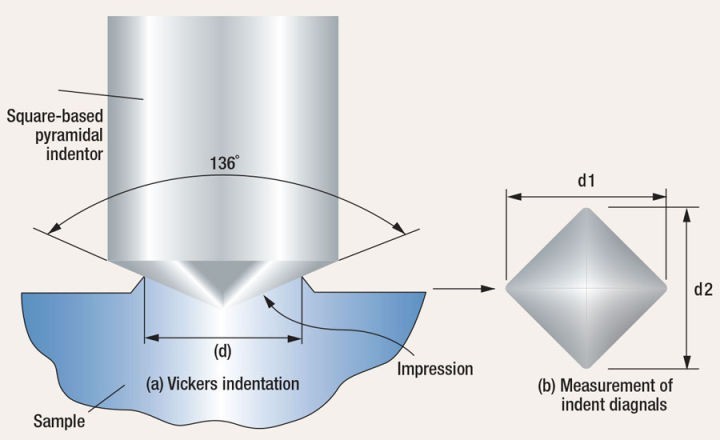

Here we first need to understand how the wear resistance of the material is defined. Typically, the laboratory measures the wear resistance of a material using the following instrument:

The basic principle is also very simple, that is, use a material with a high hardness as a reference material (usually sand), rub against the material to be tested, and then measure the amount of material to be ground. Of course, materials with poor wear resistance will be worn more,and materials with good wear resistance will be worn less.

As for the hardness, the hardness is higher for the pure material, and the higher the strength, the stronger the bond between the molecules (atoms) on the microscopic surface, the lower the possibility that the atom is peeled off by the external force, and naturally it is more wear-resistant. Many pure materials have been tested in the literature, and there is even a perfect linear growth relationship between hardness and wear resistance.

However, there are always exceptions in everything.Especially for our world today, pure material materials are far from meeting the needs of human society. Most of the materials in our lives are composite materials, including polymer composites, alloys, etc. By mixing different substances and processing them, humans obtain excellent properties that pure material materials are far from being able to achieve, but in the process, as materials become more complex, from various properties of materials Relationships are becoming more and more uncertain. To study the relationship between wear resistance and hardness, it is far from enough to start with strength. Also consider variables with more dimensions such as composition and micro structure. Here is a very simple and universal example of steel.

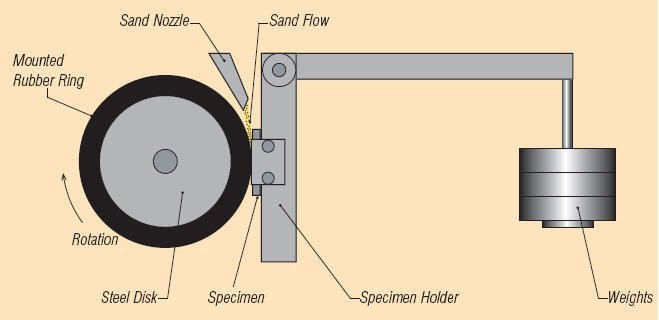

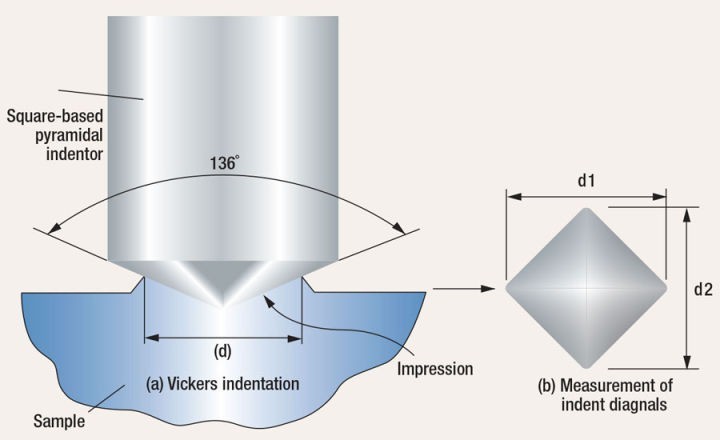

First,explain how the hardness of the material is measured, such as the following figure:

Usually, we use an indenter to press the surface of the material out of an indentation and measure the size of the indentation into a hardness. Soft material indentation is large, hard material indentation is small, yes, this is a very reasonable test method.

Above we usually call it micro hardness, but there is a problem with the measurement here, that is, it does not consider which part of the material is contributed by the hardness, such as tool steel and chrome cast iron, the hardness is 600 by this method. BHN, but the micro structure of the two materials is completely different.

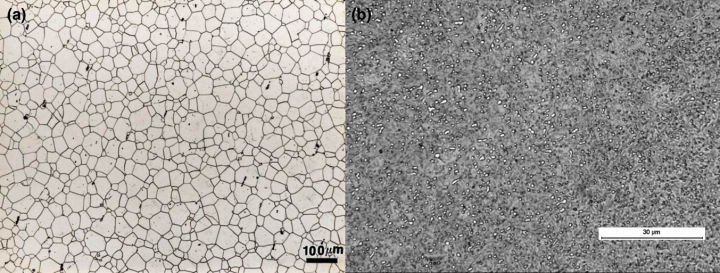

As shown in the above figure, the left picture (a) is a photo micro graph of the tool steel. The whole material is equal in size, and the hardness of each grain is almost the same, so this 600 BHN is basically anyplace of this material. The hardness of the chrome-plated cast iron in Figure(b) on the right is completely different. It is uniformly distributed with a large amount of chromium carbide. These small particles are very hard and can reach 1200 HBN, while the base of cast iron is soft. Less than 200 HBN, so for chrome cast iron, the 600 HBN comes from the weighted average of the matrix and chromium carbide.

Therefore, it is conceivable that even if the hardness is the same, the wear resistance of the material in (a) can only reach 1/5 of the material in (b), because even if the matrix of (b) is very soft, a large amount of hard carbonization is distributed. Chromium particles are the main force of wear resistance.

Therefore, micro hardness is often called macro hardness, which reflects the macroscopic properties of the material and ignores a lot of micro structure information. This is why we use macro hardness to measure the performance of different materials.

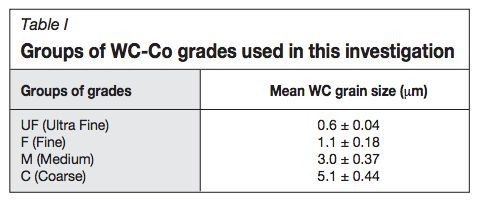

In addition, for composite materials, even if hardness can improve wear resistance, the relationship between the two is very complicated, and it is not solved by one or two formulas. For example, a WC-Co alloy can be processed to obtain different sizes of grains and hardness. Here, four grain sizes are selected as comparison groups:

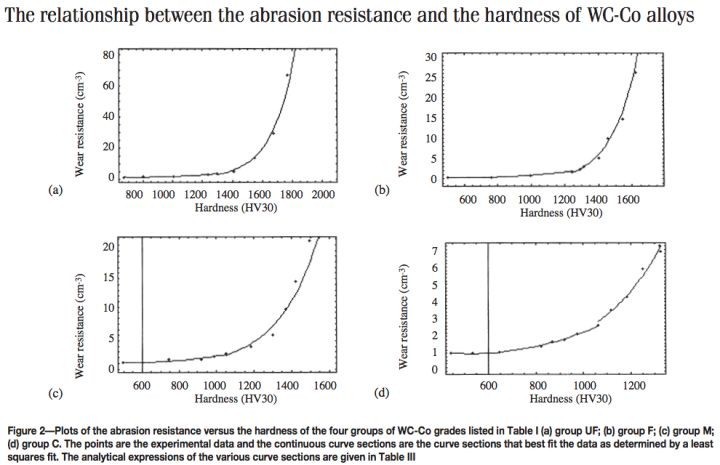

Then do the wear test, and then compare the result with the hardness, you can get the following results:

It can be seen that the increase in hardness for the wear resistance has been far less linear than the pure material material, and even has no obvious effect in the low hardness range, and has become exponentially increasing in the high hardness range. Moreover, by comparing the trends of (a), (b), (c), (d), a significant influence on the grain size can be seen.

In addition, as mentioned before, the ASTM standard method is usually used to measure the wear resistance, and there are many standard methods, each with its own focus. Therefore, the wear resistance of the materials measured by different methods may be completely different, so be careful when comparing these complicated data.

In summary, for all the materials in our lives, the hardness and wear resistance are theoretically positively correlated, and there are of course exceptions. Moreover, when comparing the hardness and wear resistance between different materials, it is necessary to consider the influence of material composition, micro structure, processing, and even the measurement method on the results. Otherwise, it is straightforward to conclude that the harder and harder the wearer is, the more bugs will occur.

Hongli tools such as pipe threading dies, pipe cutting wheels and drain augers are all need harder and more resistant materials.