HONGLI Full Teeth Milling Dies Advantage

- Share

- Issue Time

- Jun 8,2016

Among the manyfactors that influence the accuracy of the thread, the dies is the main factor . high quality dies is a necessary prerequisite for smooth threads. Hangzhou Hongli pipe machinery research focus on high quality dies formore than 20 years, we strictly control the die material detection.Nowadays the high-speed steel dies very popular inthe Global market So today let us know What’s the advantages of full teeth milinng dies.

1.Professional heat treatment , vacuumquenching ,ensures the hardness of dies .

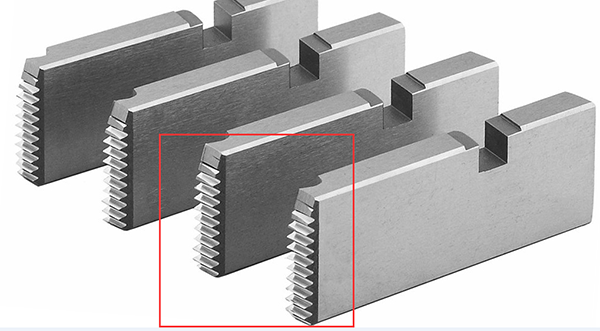

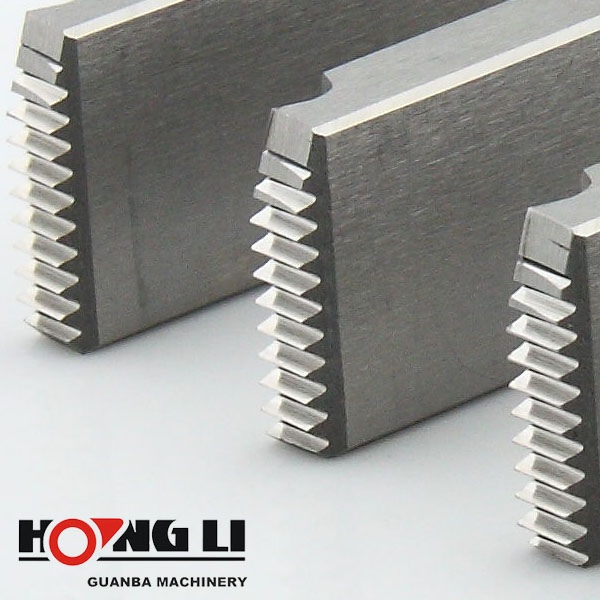

2.Full teeth milling shows more clean and smooth fineness in dies teeth.

Beveling in groove parts makes dies setting easier andfaster .This process takes more 10 minutes than othernormal dies process?

4.High quality M2 HSS material ,W6Mo5Cr4V2,from reliable material supplier, ensures the precise cutting geometry.

5.Our full teeth milling dies enjoy a long life usagewith clean threads .

After thehigh-speed steel teeth gradually escalated into full teeth milling, Obviously threading effect very good,. Many well-known European and American companies tocome to visit our comany ,they are verysatiated of our threading dies , asked us to offer them the OEM service.

In addition, Hongli also has a large selection of dietypes, including model 100, RIDGID type , REX type, ROTHENGERBER Type ,ASADA type and so on. RIDGID type dies widelyuse one model SQ50C,SQ50E,SQ50D,SQ50F (2”) ,SQ80C1(3”) SQ100F (4”)

The most common of the model 100 Dies are wildely use in chinese market such as ourmodel SQ50B1(2” ), SQ80D1(3”), SQ100D1(4”). REX type dies are widely use one the model SQ50E (2”), SQ80C1(3”), SQ100F-L(4”).

Currently, in addition to regular British and American thread die, machining range in size from 1 / 2-4 “. There metric thread die tochoose the smallest M12- M45.

We believe thatthe dies is not ony threading tool, butalso the important part of the wonderful work.